https://twitter.com/DavidRayAmos/with_replies

![]()

David Raymond Amos @DavidRayAmos

Replying to @DavidRayAmos @alllibertynews and 49 others

Methinks no doubt Higgy et al would agree that I would like to have a long talk with people such as Tom Soucy sometime soon Nesy Pas?

https://davidraymondamos3.blogspot.com/2020/05/virus-ready-poultry-producer-cant.html

#nbpoli#cdnpoli

https://www.cbc.ca/news/canada/new-brunswick/groupe-westco-poultry-covid-19-supply-chain-1.5584384

![]()

Groupe Westco, a major poultry producer in New Brunswick, has managed to keep the coronavirus at bay, but a disruption to the supply chain as hurt the business. (Mike Heenan/CBC)

This is the first instalment in a new series from CBC Atlantic called Farming your Food: How Atlantic Canadian producers are coping in COVID. We'll take a close look at the food on your plate and how it gets there, starting with some of the people responsible for that food, the producers. We'd welcome your questions and story ideas.

When COVID-19 was declared a pandemic in mid-March, Groupe Westco was ready on the safety side but caught by surprise in their supply chain.

The New Brunswick-based poultry producer, one of the province's lesser-known business success stories, is a cornerstone of the provincial food supply, raising 80 per cent of the chicken in the province.

So it could never afford to be unprepared for a fast-spreading disease. It just had to ramp up.

"Biosecurity's really important to protect the birds and to protect the consumer," said Marco Volpé, the company's senior manager. "We were already using equipment. We were already using biosecurity measures to prevent the birds from getting sick."

Even pre-pandemic, visitors had to disinfect the soles of their shoes and then put plastic boot-shaped bags over them before stepping into a Westco barn.

![]()

Groupe Westco ramped up its safety precautions in light of the pandemic, including new screening measures for employers entering a facility. (Mike Heenan/CBC)

Inside, hundreds of chicks scurry around whenever humans intrude in the dimly lit, humid space.

Nothing that touches the ground outside can be tracked into the floor of the barn.

Westco quickly imposed additional measures such as social distancing and more hand-washing, especially at its Baker Brook hatchery.

The hatchery, where thousands of chicks are born every week, is the hub of the entire operation: it's the start of the life cycle for birds that are trucked to dozens of barns around the region and that are killed and processed about six weeks later.

"If we have one guy here, one person I should say, that has COVID, everybody's got it," said Mike Michaud, the hatchery manager.

![]()

A major poultry producer in New Brunswick was ready for pandemic safety precautions but saw its distribution system disrupted by a drop in demand. 3:21

Closing the facility would be unthinkable. It would cripple the company, disrupting the supply chain for chicken for a large part of Atlantic Canada.

"It's hard for us to shut it down," Michaud said. The specialized workforce isn't easily replaced. "It's kind of tricky. It's not like you take somebody off the street to do this job."

So far, thanks to its precautions and to New Brunswick's own relatively low COVID-19 case numbers, Groupe Westco has not seen any workers contract the virus.

"We're very lucky that we don't have any COVID," said Thomas Soucy, the CEO. "Everybody's very happy to be able to keep on working.

In fact, that success has presented another challenge during the pandemic: when demand suddenly dropped off, Westco's carefully calibrated supply chain was disrupted.

What looked like a shortage of chicken was the opposite: a glut of meat on the market that couldn't reach hungry consumers.

They banded together to pool their buying power with suppliers.

Soucy, a University of Western Ontario business school graduate who grew up locally, urged them to think even bigger. They started buying up quota from farmers in southern New Brunswick who were retiring.

The next step was vertical integration: buying into other steps in the supply chain — the slaughtering, packing and selling of chicken — to reap a larger share of the profits from the value of their birds.

![]()

Groupe Westco CEO Tom Soucy says raises 80 per cent of the chickens in New Brunswick. (Mike Heenan/CBC)

They proposed to take a stake in Nadeau Poultry, the chicken processor in the village of Saint-François that had been buying their chickens. It's owned by Ontario-based Maple Lodge.

When Nadeau rebuffed Westco's offer, they found another partner, Quebec-based Olymel, to build their own slaughterhouse under a joint venture called Sunnymel.

A decade ago, Nadeau and Sunnymel were locked in a bitter legal battle. The Westco farmers were selling their chickens to another of Olymel's abattoirs in Quebec while the Sunnymel plant was under construction.

Nadeau tried to stop them, claiming Westco was trying to starve the existing plant out of existence.

Eventually things calmed down and now both processing plants operate, and even co-operate occasionally when one facility is over capacity and can't take on a shipment from one of its suppliers.

"During tough times we're able to work together," Soucy said. Nadeau officials did not respond to interview requests last week.

Westco has now become one of the dominant players in the Canadian poultry sector, with operations in six provinces. The company holds more provincially-regulated chicken quota than any other poultry producer in the country.

"Our reach is pretty significant," Soucy said matter-of-factly during an interview in the wood-panelled Westco boardroom at the head office in Saint-François.

The company slaughters 80 per cent of the chickens raised in New Brunswick, 30 per cent of those in Nova Scotia and between 15 and 20 per cent of those on Prince Edward Island. It has operations as far west as Manitoba.

Westco also raises and processes turkeys, is a co-owner of Maritime Pride eggs, which sells 70 per cent of the eggs in the Maritimes, and invests in other non-poultry ventures.

![]()

Each of the company's barns raise 500,000 chickens every eight weeks. It was forced to close 17 barns as a result of the pandemic-induced supply chain disruption. (Mike Heenan/CBC)

But raising and selling chicken is still the heart of the operation.

Dozens of its massive barns, measuring 122 metres by 12 metres, dot the winding provincial road that follows the upper reaches of the St. John River.

Each group of a dozen barns raises 500,000 chickens every eight weeks.

It was a smooth-running operation until COVID-19 hit, disrupting a delicate supply-and-demand equation.

People stopped going to restaurants, which Westco normally supplies with various kinds of processed chicken in customized cuts. Those sales dropped "almost to nothing," Soucy said.

At the same time, cooking at home soared, leading to a spike in chicken sales at grocery stores. But that didn't fully offset the decline in restaurant sales.

Provincial marketing boards slashed their quotas by 15 per cent, leading Westco to close 17 of its barns.

![]()

Groupe Westco says grocery stores don't have the capacity right now to receive and sell the volume of product the company is producing. (CBC)

But a lot of chicks and chickens were already in the system, meaning the company suddenly had a surplus of birds it could not sell.

"Most refrigerated or cold space, it's all full. It's to a point where it was costing us a lot of money to store in outside storage," Soucy said.

Customers assumed there was a chicken shortage when they started seeing signs in their local grocery stores limiting per-customer sales, but Soucy said it's a misperception.

"That's not because there's not product in the line," he said. "We have the same amount of live production that we had, and our demand went down. So there's more volume available."

The problem has been a distribution and inventory system that could not cope with a market thrown out of whack by the coronavirus.

Large grocery store chains operate on just-in-time inventory. Food arrives, is put on the shelves and is sold and replaced with more food that has just arrived.

There's a limited amount of bays for transport trucks and not a huge amount of storage at the back of the store. There simply isn't the infrastructure, or the time, to accommodate more shipments of food, even if there's a demand for it.

"Instead of, for example, getting two tractor trailers from me a week, they may need four. But they may only be able to get three because ... they don't have enough receiving slots," Soucy said.

"So they will limit the customer. If they didn't and the customer bought in bulk or bought too much, they would not have enough for everybody."

It shifted almost all its employees to positions normally filled by summer students. Only a handful of workers were laid off, softening the economic blow.

Westco and Sunnymel employ 350 people and several hundred others work at Nadeau, and the Sunnymel plant alone contributes $400,000 in property tax revenue to the rural municipality of Haut-Madawaska, said Mayor Jean-Pierre Ouellet.

"When you create one job and you know that one job supports three others, that's quite an economic impact for the Haut-Madawaska. It's a very major employer and a good employer in the area," he said.

![]()

Reduced quota forced Groupe Westco to close 17 of its barns. (Mike Heenan/CBC)

What the future holds depends on the pandemic.

With economies, and restaurants, reopening, Soucy hopes that by mid-autumn volumes will bounce back and the closed barns can reopen. Marketing boards will soon set new quotas for September.

But recovering the lost 15 per cent won't happen overnight.

"We don't think we're going to be there for many months ahead of us," Soucy said. "We think there's some restaurants that won't make it."

In the meantime, he said, Westco will keep producing chicken and keep taking precautions to avoid letting COVID-19 into its plants.

The company has given its workers a $2-per-hour pay premium to acknowledge their efforts during the pandemic, including the requirement to wear uncomfortable masks or face shields.

"We're going through a harder financial time, but we still felt we needed to compensate that in some way," he said. "It's a difficult situation. It's difficult for them.

"I certainly want to give them a thank-you for coming to work every day and feeding the people that we've fed and people that relied on us for years, and permitting us to keep our clients."

David Amos

Methinks no doubt Higgy et al would agree that I would like to have a long talk with people such as Tom Soucy sometime soon Nesy Pas?

Ray Oliver

https://tonyseed.wordpress.com/2007/04/05/maple-leaf-forever-1-maritime-workers-farmers-and-communities-to-bear-the-burden-of-%E2%80%98restructuring%E2%80%99/

David Raymond Amos @DavidRayAmos

Replying to @DavidRayAmos @alllibertynews and 49 others

Methinks no doubt Higgy et al would agree that I would like to have a long talk with people such as Tom Soucy sometime soon Nesy Pas?

https://davidraymondamos3.blogspot.com/2020/05/virus-ready-poultry-producer-cant.html

https://www.cbc.ca/news/canada/new-brunswick/groupe-westco-poultry-covid-19-supply-chain-1.5584384

Virus-ready poultry producer can't escape supply chain shock

Groupe Westco raises 4 of every 5 chickens in province, and now it's dealing with glut of product

· CBC News· Posted: May 26, 2020 6:00 AM AT

Groupe Westco, a major poultry producer in New Brunswick, has managed to keep the coronavirus at bay, but a disruption to the supply chain as hurt the business. (Mike Heenan/CBC)

This is the first instalment in a new series from CBC Atlantic called Farming your Food: How Atlantic Canadian producers are coping in COVID. We'll take a close look at the food on your plate and how it gets there, starting with some of the people responsible for that food, the producers. We'd welcome your questions and story ideas.

When COVID-19 was declared a pandemic in mid-March, Groupe Westco was ready on the safety side but caught by surprise in their supply chain.

The New Brunswick-based poultry producer, one of the province's lesser-known business success stories, is a cornerstone of the provincial food supply, raising 80 per cent of the chicken in the province.

So it could never afford to be unprepared for a fast-spreading disease. It just had to ramp up.

"Biosecurity's really important to protect the birds and to protect the consumer," said Marco Volpé, the company's senior manager. "We were already using equipment. We were already using biosecurity measures to prevent the birds from getting sick."

Even pre-pandemic, visitors had to disinfect the soles of their shoes and then put plastic boot-shaped bags over them before stepping into a Westco barn.

Groupe Westco ramped up its safety precautions in light of the pandemic, including new screening measures for employers entering a facility. (Mike Heenan/CBC)

Inside, hundreds of chicks scurry around whenever humans intrude in the dimly lit, humid space.

Nothing that touches the ground outside can be tracked into the floor of the barn.

Westco quickly imposed additional measures such as social distancing and more hand-washing, especially at its Baker Brook hatchery.

The hatchery, where thousands of chicks are born every week, is the hub of the entire operation: it's the start of the life cycle for birds that are trucked to dozens of barns around the region and that are killed and processed about six weeks later.

"If we have one guy here, one person I should say, that has COVID, everybody's got it," said Mike Michaud, the hatchery manager.

A major poultry producer in New Brunswick was ready for pandemic safety precautions but saw its distribution system disrupted by a drop in demand. 3:21

Closing the facility would be unthinkable. It would cripple the company, disrupting the supply chain for chicken for a large part of Atlantic Canada.

"It's hard for us to shut it down," Michaud said. The specialized workforce isn't easily replaced. "It's kind of tricky. It's not like you take somebody off the street to do this job."

So far, thanks to its precautions and to New Brunswick's own relatively low COVID-19 case numbers, Groupe Westco has not seen any workers contract the virus.

"We're very lucky that we don't have any COVID," said Thomas Soucy, the CEO. "Everybody's very happy to be able to keep on working.

In fact, that success has presented another challenge during the pandemic: when demand suddenly dropped off, Westco's carefully calibrated supply chain was disrupted.

What looked like a shortage of chicken was the opposite: a glut of meat on the market that couldn't reach hungry consumers.

From a small co-op to a major player

Westco started as a small co-operative created by five local chicken farmers operating along the St. John River upstream from Edmundston, a corner of the province wedged between Quebec and northern Maine.They banded together to pool their buying power with suppliers.

Soucy, a University of Western Ontario business school graduate who grew up locally, urged them to think even bigger. They started buying up quota from farmers in southern New Brunswick who were retiring.

The next step was vertical integration: buying into other steps in the supply chain — the slaughtering, packing and selling of chicken — to reap a larger share of the profits from the value of their birds.

Groupe Westco CEO Tom Soucy says raises 80 per cent of the chickens in New Brunswick. (Mike Heenan/CBC)

They proposed to take a stake in Nadeau Poultry, the chicken processor in the village of Saint-François that had been buying their chickens. It's owned by Ontario-based Maple Lodge.

When Nadeau rebuffed Westco's offer, they found another partner, Quebec-based Olymel, to build their own slaughterhouse under a joint venture called Sunnymel.

A decade ago, Nadeau and Sunnymel were locked in a bitter legal battle. The Westco farmers were selling their chickens to another of Olymel's abattoirs in Quebec while the Sunnymel plant was under construction.

Nadeau tried to stop them, claiming Westco was trying to starve the existing plant out of existence.

Eventually things calmed down and now both processing plants operate, and even co-operate occasionally when one facility is over capacity and can't take on a shipment from one of its suppliers.

"During tough times we're able to work together," Soucy said. Nadeau officials did not respond to interview requests last week.

Westco has now become one of the dominant players in the Canadian poultry sector, with operations in six provinces. The company holds more provincially-regulated chicken quota than any other poultry producer in the country.

"Our reach is pretty significant," Soucy said matter-of-factly during an interview in the wood-panelled Westco boardroom at the head office in Saint-François.

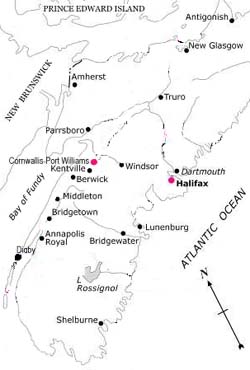

The company slaughters 80 per cent of the chickens raised in New Brunswick, 30 per cent of those in Nova Scotia and between 15 and 20 per cent of those on Prince Edward Island. It has operations as far west as Manitoba.

Westco also raises and processes turkeys, is a co-owner of Maritime Pride eggs, which sells 70 per cent of the eggs in the Maritimes, and invests in other non-poultry ventures.

Each of the company's barns raise 500,000 chickens every eight weeks. It was forced to close 17 barns as a result of the pandemic-induced supply chain disruption. (Mike Heenan/CBC)

But raising and selling chicken is still the heart of the operation.

Dozens of its massive barns, measuring 122 metres by 12 metres, dot the winding provincial road that follows the upper reaches of the St. John River.

Each group of a dozen barns raises 500,000 chickens every eight weeks.

It was a smooth-running operation until COVID-19 hit, disrupting a delicate supply-and-demand equation.

Too much supply and not enough capacity

When social distancing and stay-at-home guidelines and orders took effect in March, consumer habits changed overnight.People stopped going to restaurants, which Westco normally supplies with various kinds of processed chicken in customized cuts. Those sales dropped "almost to nothing," Soucy said.

At the same time, cooking at home soared, leading to a spike in chicken sales at grocery stores. But that didn't fully offset the decline in restaurant sales.

Provincial marketing boards slashed their quotas by 15 per cent, leading Westco to close 17 of its barns.

Groupe Westco says grocery stores don't have the capacity right now to receive and sell the volume of product the company is producing. (CBC)

But a lot of chicks and chickens were already in the system, meaning the company suddenly had a surplus of birds it could not sell.

"Most refrigerated or cold space, it's all full. It's to a point where it was costing us a lot of money to store in outside storage," Soucy said.

Customers assumed there was a chicken shortage when they started seeing signs in their local grocery stores limiting per-customer sales, but Soucy said it's a misperception.

"That's not because there's not product in the line," he said. "We have the same amount of live production that we had, and our demand went down. So there's more volume available."

The problem has been a distribution and inventory system that could not cope with a market thrown out of whack by the coronavirus.

Stores "don't have the capacity or the capabilities of receiving and selling everything that we have," Soucy said. "The production is there. We're not running out of food. We just don't have the proper distribution channels."

Large grocery store chains operate on just-in-time inventory. Food arrives, is put on the shelves and is sold and replaced with more food that has just arrived.

There's a limited amount of bays for transport trucks and not a huge amount of storage at the back of the store. There simply isn't the infrastructure, or the time, to accommodate more shipments of food, even if there's a demand for it.

"Instead of, for example, getting two tractor trailers from me a week, they may need four. But they may only be able to get three because ... they don't have enough receiving slots," Soucy said.

"So they will limit the customer. If they didn't and the customer bought in bulk or bought too much, they would not have enough for everybody."

A cornerstone of the economy

Westco managed to avoid major job losses when it closed its 17 barns in response to the quota reduction.It shifted almost all its employees to positions normally filled by summer students. Only a handful of workers were laid off, softening the economic blow.

Westco and Sunnymel employ 350 people and several hundred others work at Nadeau, and the Sunnymel plant alone contributes $400,000 in property tax revenue to the rural municipality of Haut-Madawaska, said Mayor Jean-Pierre Ouellet.

"When you create one job and you know that one job supports three others, that's quite an economic impact for the Haut-Madawaska. It's a very major employer and a good employer in the area," he said.

Reduced quota forced Groupe Westco to close 17 of its barns. (Mike Heenan/CBC)

What the future holds depends on the pandemic.

With economies, and restaurants, reopening, Soucy hopes that by mid-autumn volumes will bounce back and the closed barns can reopen. Marketing boards will soon set new quotas for September.

But recovering the lost 15 per cent won't happen overnight.

"We don't think we're going to be there for many months ahead of us," Soucy said. "We think there's some restaurants that won't make it."

In the meantime, he said, Westco will keep producing chicken and keep taking precautions to avoid letting COVID-19 into its plants.

The company has given its workers a $2-per-hour pay premium to acknowledge their efforts during the pandemic, including the requirement to wear uncomfortable masks or face shields.

"We're going through a harder financial time, but we still felt we needed to compensate that in some way," he said. "It's a difficult situation. It's difficult for them.

"I certainly want to give them a thank-you for coming to work every day and feeding the people that we've fed and people that relied on us for years, and permitting us to keep our clients."

85 Comments

Commenting is now closed for this storyDavid Amos

Methinks no doubt Higgy et al would agree that I would like to have a long talk with people such as Tom Soucy sometime soon Nesy Pas?

Ray Oliver

Reply to @David Amos: Higgs doesn't know who you are. Time for another staycation up in Restigouche

Lou Bell

Reply to @David Amos: I'd imagine Soucy has no time for you , like most you THINK want to talk to you ! Methinks Yethinks WRONG !!

Ray Oliver

Reply to @David Amos: what a legacy you leave in NB. I've been here since 1783. You embarrass your "clan" in a half hour

https://tonyseed.wordpress.com/2007/04/05/maple-leaf-forever-1-maritime-workers-farmers-and-communities-to-bear-the-burden-of-%E2%80%98restructuring%E2%80%99/

Maple Leaf Forever (1) : Maritime workers, farmers and communities to bear the burden of ‘restructuring’

Future of 380 workers from the Canard plant still remains uncertain as some may be forced to relocate and/or seek different types of work, while others destined for the Berwick plant will join workers who have lacked a union contract since 2005. News commentary by TONY SEED and ENA BOUTILIER

HALIFAX (5 April 2007, updated 1 May 2007) – HERE is an old, familiar story: workers, farmers, their families and communities are being asked to bear the burden of the striving of a large food multinational to maximize its record profits, and the government leaps forward, not to sit idly by, but to consciously participate in the placating of that monopoly. As old is the story is, it takes new form far too frequently, as it is doing so once again in Nova Scotia in the winter and spring of 2007.

Maple Leaf Foods, part of the McCain family business empire, announced on 16 January that they would close a poultry processing plant in the rural village of Canard, in the Minas Basin of Nova Scotia’s Annapolis Valley, effectively laying off all 380 of the plant’s workers as of 27 April. The corporation claimed that the 50-year-old facility is too old to be run profitably, and that such a prospect would require the doubling of its current productive capacity. The shut-down is the latest in a series of closures of food processing plants in the Annapolis Valley.

The sudden move is devastating, affecting the right-to-be not only of the workers, but also of farmers and the community. The plant is said to have a payroll worth about $11 million and economic spinoffs worth about $40 million to the surrounding communities.

The decision by the Toronto-based monopoly also directly impacts on Valley farmers, as well as poultry producers in Prince Edward Island, both of whom are facing a vicious cost-price squeeze.

The Canard facility produces fresh poultry products, including branded and private label branded chicken, primarily for customers in Atlantic Canada. It processes approximately 250,000 locally-grown chickens each week, which came from about 20 poultry farmers. The closure of the Maple Leaf operation leaves rival ACA Co-operative as the only federally-inspected Nova Scotia processor. It has agreed to take 40,000 birds from a handful of farmers. Some 83 poultry farmers in the province produce about 43 million kilograms of chicken each year, according to the Chicken Farmers of Nova Scotia. Others are having to export to New Brunswick and Nadeau Poultry of St. Francois-de-Madawaska, owned by Maple Lodge Farms of Ontario – which means higher shipping costs. And its parent company is the third-largest chicken processing company in Canada.

Maple Leaf Foods is owned by Wallace McCain, formerly co-CEO of McCain Foods, along with the Ontario Teachers’ Pension Plan. The corporation is also one of Canada’s largest agribusinesses, Canada’s largest pork and poultry processor – and also owns poultry and hog farms across the country. This multinational employs approximately 24,000 people at its operations across Canada and in the United States, Europe and Asia, and had sales of $6.1 billion in 2005. Its 2003 merger with rival Schnieders Foods gave it control of 80 per cent of the pork-packing industry in Canada.

In response to the announced closure of the Canard plant, the Nova Scotia Department of Education set up a “transition office” at the plant in what it said was an effort to explore career prospects and retraining possibilities for employees, as well as an effort to offer consultation on issues like employment insurance. The office was being set up in partnership with Maple Leaf Foods, the United Food and Commercial Workers Union, and Service Canada. As of press time, only 58 workers have found other jobs, and less than 60 per cent of workers had responded to the employment and training services being offered.

Middleton; rising unemployment in the Annapolis Valley

The closure of the Canard plan is, in various ways, merely the tip of the iceberg wreaking havoc in rural Nova Scotia. In the great fertile Annapolis Valley prosperity, like a guardian angel, is supposed to dwell. Here is great wealth in fat herds of cows, pigs and chickens, in fruit, vegetables and all manner of lesser farm produce. Truly a fat land and of course its inhabitants are well off; jolly, contented farmers. At least so say the newspapers, real estate sharks and retirement pamphlets issued by the counties courting well-off seniors to retire to the Valley. But stores are being boarded up and schools closed.

For the Annapolis Valley, the shutdown is part of a calamitous series of plant closures stretching back to 2003. Just the previous week, a decision by TRA Foods, owned by the Sobey’s family empire – “due to internal restructuring and job realignments” of their whole sale division – cost another 30 jobs due to Sobeys’ closing its administrative offices in the town of Middleton, also in the Annapolis Valley.

TRA Foods began operating in 1950 as a dry grocery products wholesaler in Middleton and was purchased by Sobeys Inc. in 1957. Sobeys is the second largest retail food distributor in Canada with annual sales of over $12 billion while employing 32,000 people. Since then, TRA has expanded into all of Atlantic Canada as a wing of the Sobeys’ empire. According to Canadian Grocer E-Newsletter (December 15, 2006), Sobeys’ parent Empire Company reported a profit rise in the 4th quarter of 2006, with earnings reaching $57.2 million, up from $48.6 million a year ago, with revenues reaching $3.31 billion (up 2 per cent).

Port Williams

In 2004 the closure of the last vegetable canning operation in Atlantic Canada, Avon Foods in the nearby village of Port Williams, not only affected workers but also producers who lost a large share of their income.

With the closure of the Britex textile plant at Centrelea near Bridgetown in October, 2003 with just over $4.4 million in unpaid loans to the provincial government, and Maple Leaf’s Shur-Gain livestock feed mill in Port Williams (and in Sussex, NB and in PEI) in 2005, the resulting layoffs put over 200 people out of work. According to Statistics Canada, Annapolis Valley employment is up just slightly from January, 2006 but the unemployment rate is down substantially from 9 per cent. Six per cent is the lowest January unemployment rate recorded for the Annapolis Valley for at least the last 20 years but this figure is a mirage. This is because the Valley’s labour force is smaller this year by almost 2,000 people, a figure that does not include the 380 workers to be laid off this April at Canard by Maple Leaf Foods.

Maple Leaf (Larsen’s) in Berwick

Meanwhile, 400 workers employed by a Maple Leaf-owned pork processing plant (Larsen’s) in the town of Berwick (pictured), further south in the Annapolis Valley – represented by the Atlantic Meatpackers’ Union (AMU) – voted on 17 January, the day after the Canard announcement, to reject a contract that was offered by the company. Larsen’s workers had been without a contract since September 2005, a 16-month period.

Widespread speculation is also being generated about this plant’s future. News of difficulties for workers in both Canard and Berwick come as Maple Leaf is now aiming to consolidate its meat processing operations throughout the country in Brandon, Manitoba after having decided in October, 2006 to exit the pork export industry. And much of the Larsen’s plant production is geared for export.

Larsen’s takes 80 to 85 per cent of Nova Scotia’s pork production from hog producers.

Despite the pressure on the workers, Ted Jones of the AMU said, “We weren’t scared – we’ve heard the rumours every time we’ve been through a contract, and we’re tired of them. We’ve been through wage freezes, rollbacks – we deserve it for all we’ve done to help the company get through things.”

Maple Leaf offered a 25 cent hourly increase in September of both 2007 and 2008, but did not live up to union demands in terms of pension and sick benefits, retroactive money and signing bonuses. Many workers are leery of the long-term future of the Berwick plant. Superficially, there are no apparent plans to close the facility as in the case of Canard. In fact, plant manager Mike Larsen publicly stated he will consider hiring former Canard workers in the Berwick plant, a statement made shortly before news broke of the creation of the Canard facility’s transition office on January 24. Nevertheless, he acknowledged “quite a migration of Larsen’s workers” has taken place. The AMU’s Jones adds: “We’ve lost 100 people in there the last year,” citing the lure of Western Canadian jobs and regional insecurity as enough incentive to attract even settled families. “It’s hard to get people.”

The tombstone of rural Nova Scotia

The rationale of Maple Leaf’s current “restructuring” efforts is strongly reminiscent of actions taken by other key monopolies in the food processing industry. In 2005, for instance, Québec pork and poultry producer Olymel, a division of Qu?bec’s huge La Co-op fédérée and a rival to Maple Leaf Foods, threatened to consolidate operations in St. Bonifice, Manitoba (in a joint plant with Saskatchewan-based Big Sky Farms and Manitoba’s Hytek). It declared it wanted to close several facilities in Québec on the grounds that it needed to modernize its production units in the interest of being both nationally and globally competitive. Recently, on 13 February 2007, it forced Olymel workers in Vallee-Jonction, Quebec, to vote to accept massive wage cuts in order to return to work under the spectre of the threat of closure.

In the case of workers from the Canard plant in Nova Scotia, their future remains uncertain. Some may be forced to relocate and/or seek different types of work or go down the road, while others destined for the Larsen’s plant in Berwick will join the other workers who have lacked a union contract since 2005. The burden of the crisis is put on the backs of these workers, the poultry and hog farmers, the main street business people and their communities, and their very right to be, leaving ruin in our rural communities.

Even if they are lucky enough to remain employed, workers are being shuffled from one location to another without regard to the costs of transportation and relocation, while small rural communities such as Canard and Port Williams suffer a decimation of a significant part of its economic base – all under the watchful eyes of our elected officials, working hand in hand with one of the region’s richest business families. In the same way, the monopolies shift meat and feed grain supply from region to region and country to country and strategically locate their operations to maximize profits and externalize costs, regardless of the consequences to either the farmers, the region or the nation. Meanwhile, they blame the wages of the worker and the prices of the farmer or the catch-all euphemism of “rising energy costs” for rising food costs to the consumer.

The vertical integration of the food industry means that a handful of huge packers, through their direct and indirect control of corporate industrial farms, and the elimination of the “single desk” selling system, dictate monopoly prices through contracts with large beef and hog producers, eliminating the market power of the small- and medium-sized family farm producers. Through exclusive contracts with the supermarket chains – Sobeys, Atlantic superstores and Wal-Mart, etc. – this cartel is squeezing all non-monopoly competition, from independent meat-packing facilities to independent retail chains such as the co-ops. “Similarly, organic agriculture must be destroyed,” notes the Union Farmer Monthly to cut off the escape route from the factory-style farm.” They provide “forms of resistance, and they provide a working counter-model.”

At the same time, the consumer who tries to respond to the niche marketing programs to “buy local” is blocked by generic private-label or unbranded goods, such as Sobeys “Our Compliments” and Atlantic Wholesale’s “President’s Choice”, which make it impossible to discern where and from whom the product originates.

Protection of the local marketplace and the local market infrastructure to facilitate direct links between the farmer and the consumer is important, but the “buy local” program seems to have another role: to suggest that the source of the problem lies with the tastes of the consumer, that the problem is primarily one of consumption, and that the solution lies in appeals to the non-existence conscience of the supermarket chains. It depoliticizes the consumer from taking a stand with farmers and labour. Of course, Sobeys et al do “buy local”, mostly perishables, cheaply positioned behind the major display and prime shelf space paid for by the large food monopolies.

This is symptomatic of a larger national political problem. All political decision-making is in the hands of relatively few people – all of whom accept without question the dominant paradigm of global competitiveness as a goal to be pursued at all costs. Parties in power federally, in Alberta, and elsewhere, most notably in the US, are waging an extensive campaign to turn over all aspects of food production and distribution to these transnationals such as Maple Leaf Foods, Cargill and Tyson. In the name of “competitiveness”, “efficiency”, “free market” and “food security” agencies such as the Fraser Institute, the Calgary School, the Frontier Centre, and the Atlantic Institute of Market Studies are campaigning to eliminate equalization payments and price support to small farmers. The defence of private wealth and its future expansion is the basic consideration of these parties and “think tanks.” The monopolies lay off workers and block their unionization, wipe out farmers, and devastate communities and entire regions because they can.

What official political leadership in this province or the nation has had the courage to uphold its responsibilities towards the society, to defend the public good and stop the attacks of the monopolies? You want the supercentres open on Sunday? There’s no problem: Corporate Research uses polling to prove the case; the media, lusting for Sunday advertising, campaign for consumer secularism; the police tolerate violations of bylaws by the supercentres; and the big tourist interests justify it as a means of attracting cruise ships. In the name of global competitiveness, the workers in Berwick – as at Vallee-Jonction, Québec, or in the forest sector and their communities, such as what transpired with Stora Enso in Port Hawkesbury last year – are being intimidated with the long-term possibility of closure into accepting working conditions that they would not accept in any other circumstance.

The fruits of the earth, the rights and existence of workers, the small to medium-sized holdings of the farmers, their communities and even the factories and mills owned by big capital are considered dispensable within the fundamental aim to defend and expand monopolies and their empires. The sole solutions being proffered are to go down the road or the canard of buying fresh food and farm products locally.

Self-sufficiency in food is an important element of national sovereignty. The cases of Canard and Berwick are a graphic illustration of the need for new political leadership – a leadership that stops paying the rich, develops a national economy including regionally-self reliant agriculture and food, upholds social responsibility, invests in social programmes – and new political mechanisms that make such governance possible.

Only then can this old, familiar story truly become an artifact of the past.

Originally published on Shunpiking Online, May/June 2007